Selecting a Vacuum Sweeper for Clean Air

A dusty factory floor creates a poor breathing environment.

Case Studies on practical and safe solutions to unique dust, fume and mist applications.

These case studies and essays provide insight into our various experiences in facilities across the USA, where we solve air and dust problems for our clients.

A dusty factory floor creates a poor breathing environment.

If you are renting expensive vacuum trucks your ROI on purchasing an ATLAS is instant.

If you see a "buy-it-now" next to a picture of an explosion-proof Vacuum or Dust Collector, this indicates a brand that cannot and should not be trusted.

Water is your filter in a wet collector, and it is only efficient to 10 microns

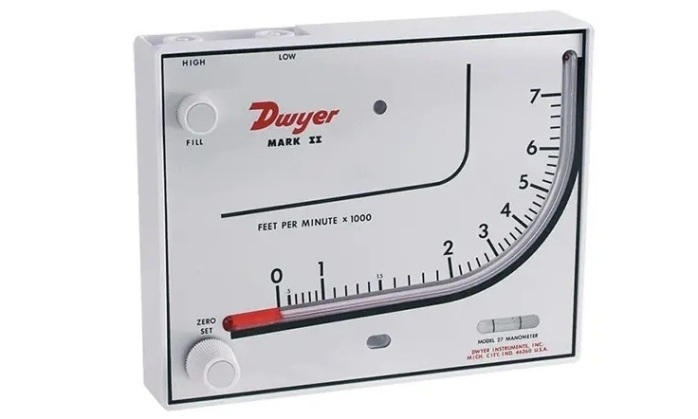

Industrial ventilation typically employs supply and exhaust systems to manage emissions, exposures, and chemical hazards in the workplace.

OSHA requires a Capture Velocity of 150-300 fpm and a conveying velocity of 3000 to 4000 fpm