Dust Collector for Granite and Silica

Cabinet-Style Dust Collector for multiple operators producing dust at one time.

HEPA Filtered Booth Module

Stone Countertop Cutting Produces Harmful Silica Dust

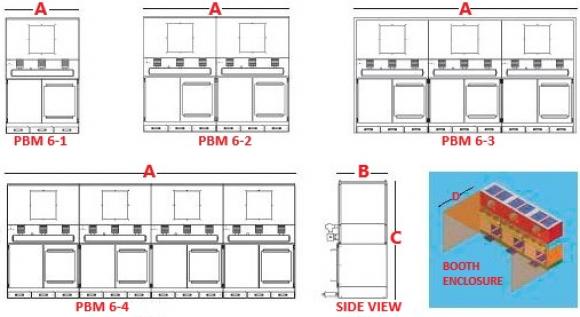

Stone countertop cutting produces harmful silica dust, so we developed a powerful capture solution that has OSHA-specified HEPA modules for more efficient control and the capture of dust inside a booth. As the size of your booth increases, the number of PBM units increases to maintain a high cross-sectional air velocity inside the booth and prevent the operator from breathing airborne dust. Options for the inlet of the PBM unit consist of hinged side wing doors, metal mesh for sparks, or louvers. When the side wing doors are opened at an angle, the dust capture efficiency improves, creating a funnel of air and drawing the airborne dust into the unit more effectively.

Click HERE to see a Case Study for OSHA Silica Standard

Push-Button Compressed Air Filter Purge

Push button compressed air filter purge and we also have an option for AUTOMATIC filter purge that is based on reading a pressure drop. Essentially when the filters get plugged, the sensor reads the blockage and automatically forces high pressure compressed air through the filters so you can continue working with no downtime.

Our OSHA Compliant HEPA Filters, With a Remarkable 99.97% Efficiency at .3 Micron

Our OSHA-compliant HEPA filters, with a remarkable 99.97% efficiency at .3 micron, ensure that harmful dust particles are completely scrubbed, providing a safe environment for everyone in the area. They also prevent the spread of silica dust into adjacent offices, enhancing overall safety.

Basic PBM units include either four or six pleated cartridge filters rated at 99% efficient.

The PBM Units Feature a Reliable and Efficient TEFC Continuous-Duty Baldor Motor

The PBM units feature a reliable and efficient TEFC continuous-duty Baldor motor, controlled and protected by a manually operated adjustable fused disconnect switch. This ensures consistent performance and peace of mind for our customers. Servicing the PBM is a breeze, thanks to the easily accessible filter or Magnehelic gauge. This feature provides convenience and peace of mind, ensuring the unit is always in top condition. Less maintenance on the PBM is due to the tremendous amount of filter surface area.

- Manufactured using 11- and 14-gauge steel and painted with a heavy industrial powder-coated textured finish for harsh environments

- Flexible and multiple uses for the PBM are achieved by offering a variety of air inlet choices

- Quiet operation

- Energy savings provide a rapid return on initial investment

- Meets or exceeds OSHA requirements

Silica Dust from Granite Cutting is Harmful to Your Lungs

Silica dust from granite is harmful to your lungs. We can calculate how many CFM you need based on shop measurements and how many operators are cutting or sanding stones simultaneously. That huge dust cloud gets sucked into the cabinet, and clean air is exhausted back into the space without losing heated or cooled air.

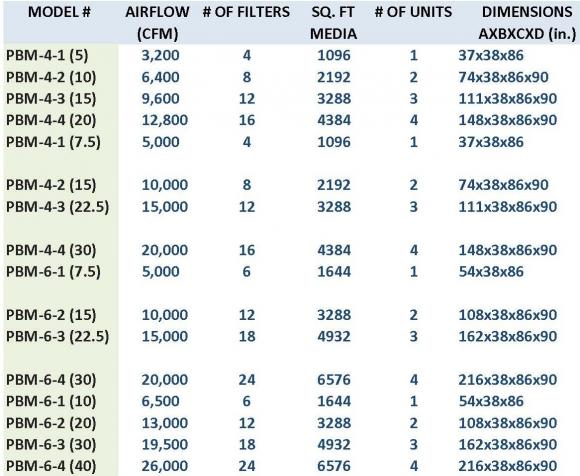

Specifications:

Calculate How Many Units You Need by this Chart

Push-Pull System

The Push-Pull System Keeps Heated and Cooled Air Inside

The push-pull system keeps heated and cooled air inside where the exhaust from the PBM is using the clean filtered air to force airborne dust back towards the dust cabinet in a closed-loop push pull system. This method can save a lot of energy costs. Call us with the details of your application and we will provide a solution.