All day laser cutting of aluminum was creating a lot of smoke

Proper filtration was needed for all day cutting

The Challenge

A metal fabrication shop contacted us with a problem they were experiencing while cutting sheets of aluminum. They still faced a significant issue, as the dust produced in that process tends to be dirty and quickly clogs the pores of standard dust collection cartridge systems. A suitable solution that provided the appropriate amount of air and filter area, as well as the correct type of filtration, was essential.

The Solution

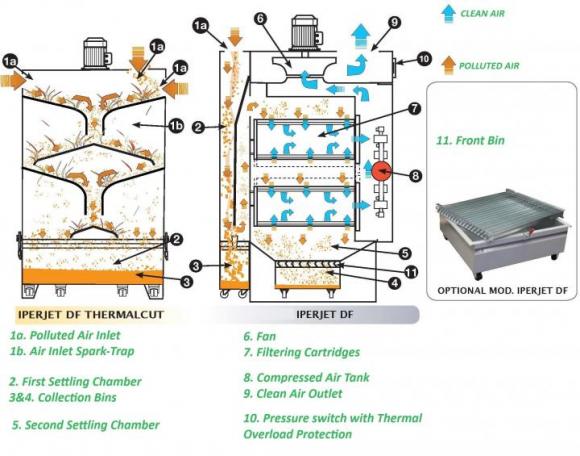

We recommend the Coral HORIZONTAL CARTRIDGE FILTER MODEL IPERJET DF9 MAX TC. Its unique interior design directs fumes and dust through a series of deflectors and spark traps, significantly reducing the amount of particulate that reaches the filters. The filters are made of NANO-web cartridges, which allow sticky particulates to glide off.

The unit features an automatic compressed air cleaning system. When it detects a pressure drop, it releases a pulse of air through the cartridge filters. In total, there are nine filters that provide ample filter surface area. The interior of the TC is specifically designed to minimize the amount of particulate on the filter. This solution is ideal for all-day, messy laser cutting of aluminum.

Water bath at the bottom of the spark chamber

The client reported that the Coral HORIZONTAL CARTRIDGE FILTER MODEL IPERJET DF9 MAX solved their issues. Now they can cut aluminum all day without worrying about fixing an undersized portable collector. This solution has proven to be an effective piece of equipment for the end user.