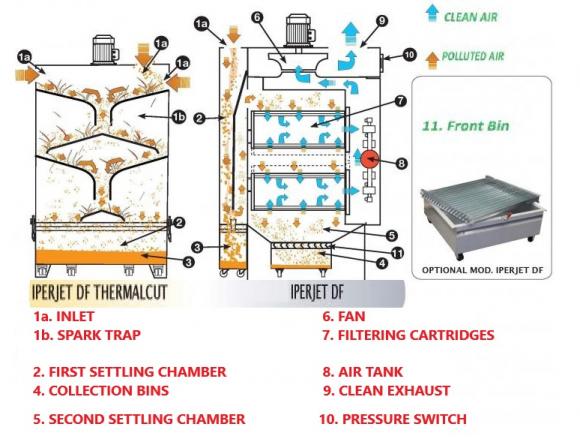

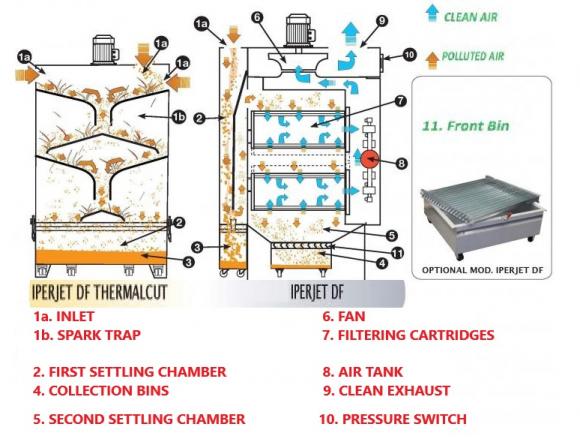

Click for Interior Spark Chamber Diagram

Dust collection of fumes from all-day robotic welding and laser cutting applications. Returns clean breathable air into work space.

Up to nine filter cartridges are available in the different versions of Iperjet for safe collection of heavy dust from cutting and welding of metals that produce a lot of fume. The onboard AUTO filter cleaning system is set up for hands-free operation. The starter is set up with a thermal overload switch. With a spark-extinguishing chamber, FR filters, and an option for a HEPA after-filter that is 99.97% efficient @ .3 microns, the Iperjet returns clean, breathable air into the workspace.

Click HERE to see some of the options and accessories for the IPERJET.

DF - Dust Collection

TC - Thermal Cutting

Dry powders or sticky welding smoke can present a different set of challenges so there are two distinct versions of Iperjets depending on what the collector is to be used for.

We like to have a detailed conversation about the application so that we can recommend the right unit for your needs, whether it is extraction of fumes from grinding, de-burring, laser and plasma cutting, or if it is being used for dry dust collection.

Click HERE to see full specifications.

The Thermal Cut or TC is for extraction of fumes from grinding, de-burring, laser and plasma cutting, welding, marking, and much more.

Aluminum cutting and welding produces heavy smoke. A small portable welding fume collector with a small cartridge filter would get overwhelmed in no time and the filters plug up. For heavy dust and fume applications we like to recommend the Iperjet. We have four, six, and nine filter cartridges for heavy dense smoke, as well as a drop out chamber and AUTO-pulse filter cleaning. For all day aluminum cutting or welding you need that much filtration.

The baffled walls of the interior of the TC are specially designed to cope with heavy sparks and fumes produced from all day operation of laser and plasma cutting, or etching applications. The range of filters and AUTO cleaning design make the Iperjet TC ideal for production or robotic cell uses.

The DF is for source collection of dry powders at multiple points around a production area. It can also be used as a portable as it sits on heavy-duty locking wheels.

In a lot of applications the DF sits in a designated area with metal ducting running to the collection points. The interior of the DF is set up for rapid collection of fine dust and fully integrated sub-micron dust filters that return clean breathable air back into the workspace.

Proper source-capture at the point of operation means that the HVAC system doesn’t redistribute that dirty air through vents to offices and work areas. Capturing of the smoke and VOC at the source is by far the safest method for overall air quality. Once the toxic fume is captured it is dealt with. Ambient type, or ceiling mount collectors don't stop the fume from going into the HVAC system and into office and work areas. Source capture is the only safe way to do this.

Horizontal cartridge filters with an internal spark trap design are suited for grinding fumes, fine and coarse dust, small quantities of chips, and dust/fumes from thermic cutting. This filter is to be used inside work premises.

Delivering as much as 3,835 cu ft/min, plus HEPA and Carbon Filtration options. This is a very powerful unit with a lot of filtration for heavy dust loading applications like all-day cutting of aluminum or plastic.

Plastics can give off nasty odors, so we have a carbon cell that can greatly help with reducing VOC.

Most portable collectors can't handle heavy fumes from aluminum welding, which are very tricky to handle. The combination of unique design, lots of airflow, and cleverly placed filtration makes the Iperjet the number-one choice for aluminum cutting and welding in major manufacturing around the world. The horizontal position of the cartridges allows easy access and quick maintenance of the filtering area. The filtered air is recycled back into the working area, saving considerable energy.

Most of the coarse dust is separated in a pre-chamber, so it settles in a first collection tray. The air then runs through a maze and reaches the filter section with high-efficiency cartridges, which filter any remaining dust. In the upper part of the Iperjet cartridge filter, there is a high-efficiency centrifugal fan, which guarantees a high suction capacity while maintaining low noise levels.

| Unit | DF4 | DF6 | DF9 |

|---|---|---|---|

| Air Flow | 1770 cu ft/min | 2360cu ft/min | 3600 cu ft/min |

| Useful Static Pressure | 5.1 inches H2O | 3.93 inches H2O | 5.11 inches H2O |

| Weight | 836 lbs | 1034 lbs | 1364 lbs |

| Working Tank Header Pressure | 116 psi | 116 psi | 116 psi |

| Voltage | 230 or 460/3/60 | 230 or 460/3/60 | 230 or 460/3/60 |

| HP | 3HP | 5.36HP | 10HP |

| Sound Level [*Silencer Plenum] | 78 db / 71 db* | 81 db / 75 db* | 87 db / 79 db* |

| Filtering Surface (f²) | 398 | 775 | 1162 |

| Bin Capacity (G) | 22 | 24 | 29 |